Not all high performance vehicles are in need of high performance brake fluid, but highly abused braking systems can benefit from a racing formulation. During periods of high frequency braking, excessive heat builds up in the system, causing brake fluid temperatures to increase.

If the brake fluid temperature increases too much, the brake fluid itself will boil and cause brake pedal “fade”. If this has ever happened to you, bleed your brakes and upgrade to a higher dot grade of brake fluid upon replenisho familiar with brake fluids and their DOT grades, you should review of the pros and cons of each type before choosing a brake fluid for application.

Brake fluid comes in either DOT 3, 4, or 5 grades, and the properties of each are standardized by the government. Each DOT standard certifies properties such as viscosity, temperature, chemical stability, corrosiveness, water tolerance, compatibility (between formulations), and effects on brake system components for safety. It is important for drivers to rely on manufacturers claims, as brake fluid instability can cause unsuspected braking failure.

Out of these standards tested, the ones that apply to performance braking are as follows:

| Standard |

Composition |

Dry Boiling Point |

Wet Boling Point |

| DOT 3 | polyalkylene glycol ether | 401 | 28 |

| DOT 4 | polyalkylene glycol ether and borate esters | 446 | 311 |

| DOT 5 | silicone oil based with additives | 500 | 356 |

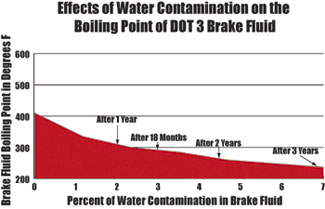

DOT 3 and DOT 4 brake fluids are hygroscopic, meaning they have a high affinity for water and chemically attract it. If moisture enters the braking lines, this moisture is absorbed so that it will not create a negative effect on the braking system. If water were to get in to the hydraulic system of brakes, it could affect braking performance and increase the chances of brake component oxidation.

The main drawback, however, of using these brake fluid types is a reduced boiling point. If you are running a race or applying brakes frequently, this reduced boiling point can cause your brake fluid to boil unexpectedly.

DOT 5 brake fluid uses a more viscous mixture that resists water. If water happens to enter your brake system lines while using it, it will sit at the bottom of your braking system where it can oxidize your system. Because DOT 5 brake fluid does not absorb water, it will not boil as easily, thereby allowing you to run your brakes much harder.

system lines while using it, it will sit at the bottom of your braking system where it can oxidize your system. Because DOT 5 brake fluid does not absorb water, it will not boil as easily, thereby allowing you to run your brakes much harder.

Silicone based fluid may create more mush in your pedal, but will be more predictable overall as the fluid will not compress as easily. By keeping brake fluid temperatures under 350 degrees Fahrenheit, you can expect constant performance from the DOT 5 brake fluid.

Between the DOT 3 and DOT 4 class of brake fluids and the DOT 5 class, water affinity is the main difference between them. DOT 4 has a slightly higher affinity for water than DOT 3, while DOT 5 has no water affinity whatsoever. Because boiled water compresses very easily, it is undesirable to have in any performance braking system.

*Source http://www.superoilcentral.com

Tips On Adding DOT 5 Braking Fluid

Any gas is undesirable in the braking line, so pay special attention when pouring the DOT 5 in the master cylinder. A heavy pour will entrain air in the process.

Don’t use DOT 5 braking fluid in ABS braking systems as air containment through cavitation happens very easily and can destroy associated parts.

If you decide to upgrade your braking system heat capacity by upgrading to a larger mass rotor, then a DOT 5 braking fluid can be a great addition to the process. I recommend doing both if your braking system is setup for it.