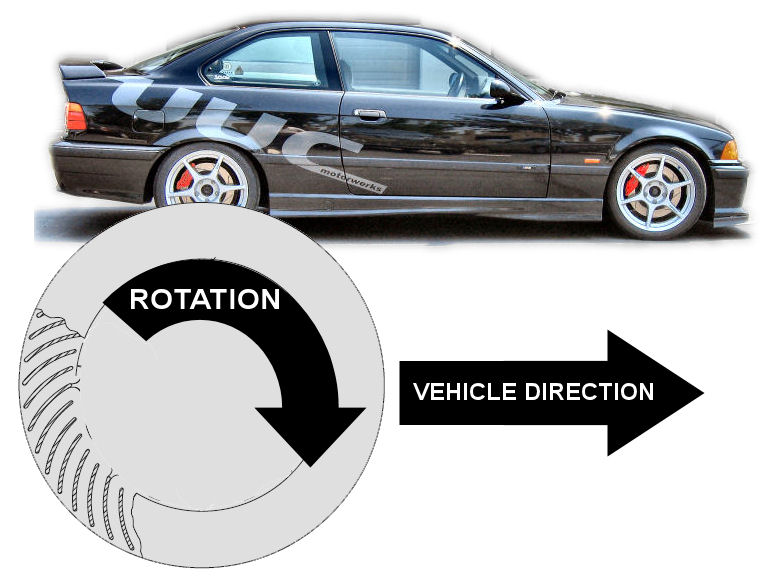

The benefits of using drilled brake rotors vs.stock blanks are many, but drilled rotors have their drawbacks as well. While a drilled brake rotor will cool much easier than a standard blank rotor or slotted rotor, the drill sites are prone to cracking.

There are different techniques for drilling a brake rotor, and later honing it to perfection, to prevent the chance of a crack, and we will discuss these techniques in this article.

First of all, we are going to explain exactly what causes a rotor to crack.

If you have ever taken a glass and heated it up, then quickly put itunder some cold water, then you may have witnessed “temperature change” stress cracking. This is essentially what happens to a brake rotor when it cools down too fast after becoming superheated. The stress of cool...

Read More

* Source: forums.bimmerforums.com

* Source: forums.bimmerforums.com * Source: f1-dictionary.110mb.com

* Source: f1-dictionary.110mb.com